PFJ Mouldings, S4S, Jambs and Smalls

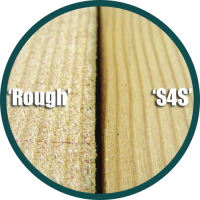

Woodstock Timbers mouldings are manufactured from 100% sustainable radiata pine, from Chile, NZ, Brazil and Australia. The timber is then finger jointed to produce a quality timber moulding in many sizes, finished with a single coat of acrylic primer for the ultimate smooth finish.

We have all sizes available from shoe products, through to S4S and architrave and skirtings. We offer a door to door service for 40’ FCL orders only, as we manufacture to order from our Factories in both Malaysia and Indonesia.

Due to some of the current Pine shortages, we are also experimenting with Scottish Pine and Rubberwood but do not mix our containers with different kinds of wood fibre.

Please call to discuss your requirements as we are looking to partner with only a few select Customers in the US, so we can always offer you the best service and attention. Current lead times for production only, is around 6 weeks from receiving your confirmation.

We look forward to hearing from you, and discussing the opportunity for a long term mutually rewarding business relationship together.

Facts Sheet

Items

Keypoints

Specific Requirements

North America products only accept live knots less than 2.0cm 2.0cm in diameter.

Wood defects include Pitch Pocket, Heartwood etc.

Items

Keypoints

Specific Requirements

Keypoints

Specific Requirements

Keypoints

Specific Requirements

Keypoints

Specific Requirements

Keypoints

Specific Requirements

Items

Keypoints

Specific Requirements

To avoid the potential wrapage risk for exterior jamb, the length

of every single blank is between 300 mm to 400mm.

The length of the fingers is between 7mm and 11mm.

For all small profiles, the fingerjoint glues are applied on both ends.

Keypoints

Specific Requirements

Keypoints

Specific Requirements

pin holes is dug out first. Then all the holes must be filled

with 502 glue and sawdust. All surfaces must be flat and smooth.

All the knots and heart pith on four sides must be sealed by

oil-based sealer.

Keypoints

Specific Requirements

Keypoints

Specific Requirements

allowed on product front and back surfaces.

S3S Board back need improved, no obvious chain marks on back

Items

Keypoints

Specific Requirements

101 Sheridan St, Cairns

QLD 4870 Australia

ray@woodstocktimbers.com

Phone: +61 419 022 683 (AUS)

Phone: +1 407 730 1452 (USA)